Car window tinting film is considered an effective and simple solution for insulating car windows, particularly as it does not affect visibility. The main function of the film is to block the heat from the sun from passing through the car windows. This type of film can be applied to all glass positions of the car, including: windshield, side windows, quarter glass, rear window, and sunroof.

Automotive window tinting films are usually made from Polyethylene Terephthalate (PET), combined with various treatment methods that allow the film to reduce heat transmission through the glass. There are two main product lines of insulation films: automotive window tinting films and architectural window tinting films.

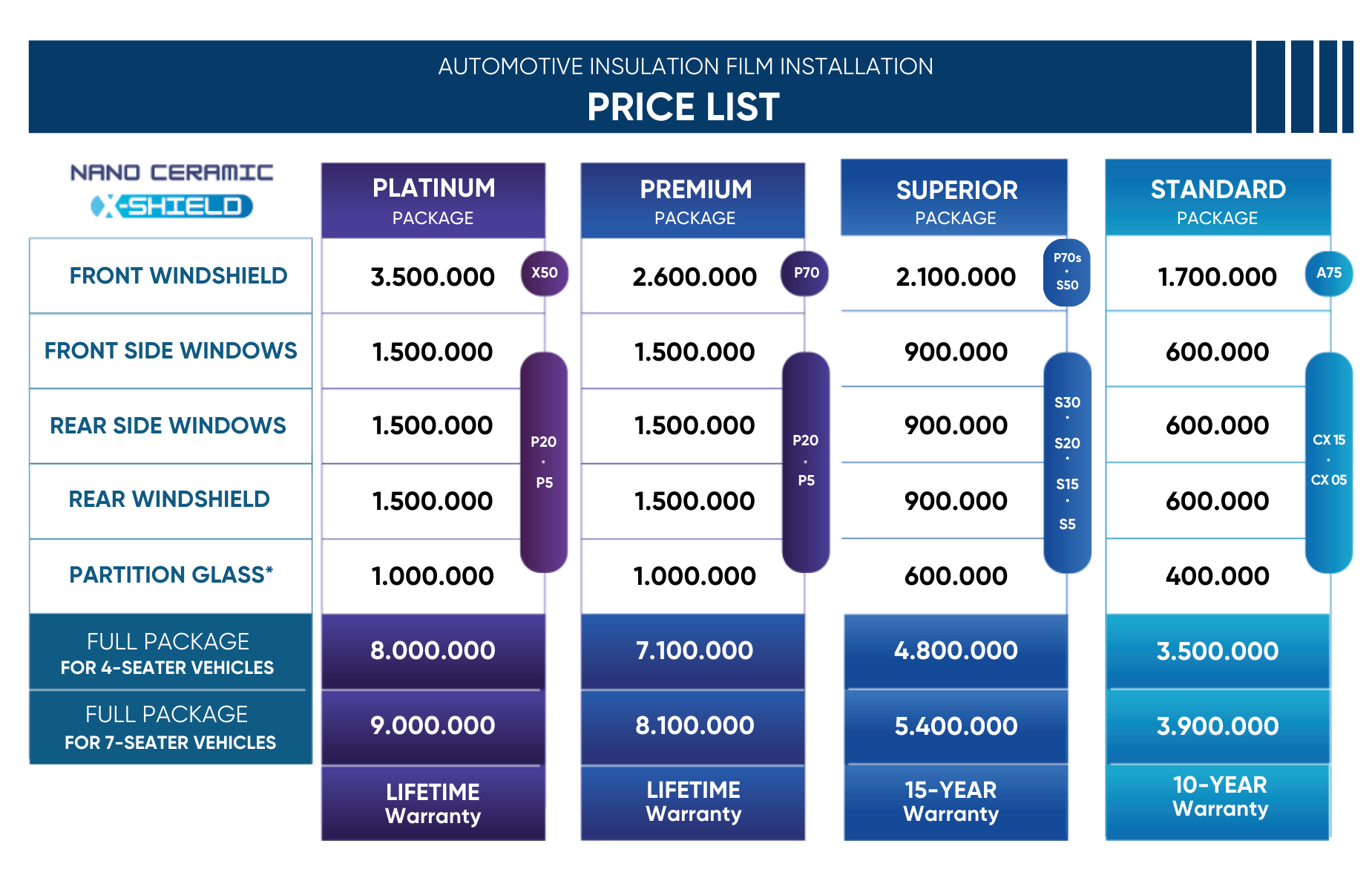

Price list for NanoX car window tinting film and technical specifications

Price list for NanoX car window tinting film (effective from 01/01/2025):

| NanoX Automotive Window Tinting Packages | Car Type | Package Price (VND / Full Vehicle) |

|---|---|---|

| Platinum Window Tinting Package | 4-seater | 8.000.000 VND |

| Premium Window Tinting Package | 4-seater | 7.100.000 VND |

| Superior Window Tinting Package | 4-seater | 4.800.000 VND |

| Standard Window Tinting Package | 4-seater | 3.500.000 VND |

| Platinum Window Tinting Package | 7-seater | 9.000.000 VND |

| Premium Window Tinting Package | 7-seater | 8.100.000 VND |

| Superior Window Tinting Package | 7-seater | 5.400.000 VND |

| Standard Window Tinting Package | 7-seater | 3.900.000 VND |

Technical specifications for automotive window tinting film package

Note:

Note:

- Full package for 4-5 seater vehicles: 3,500,000 – 8,000,000 VND

- Full package for 7-seater vehicles: 3,900,000 – 9,000,000 VND

- Free on-site installation for full package orders within Ho Chi Minh City.

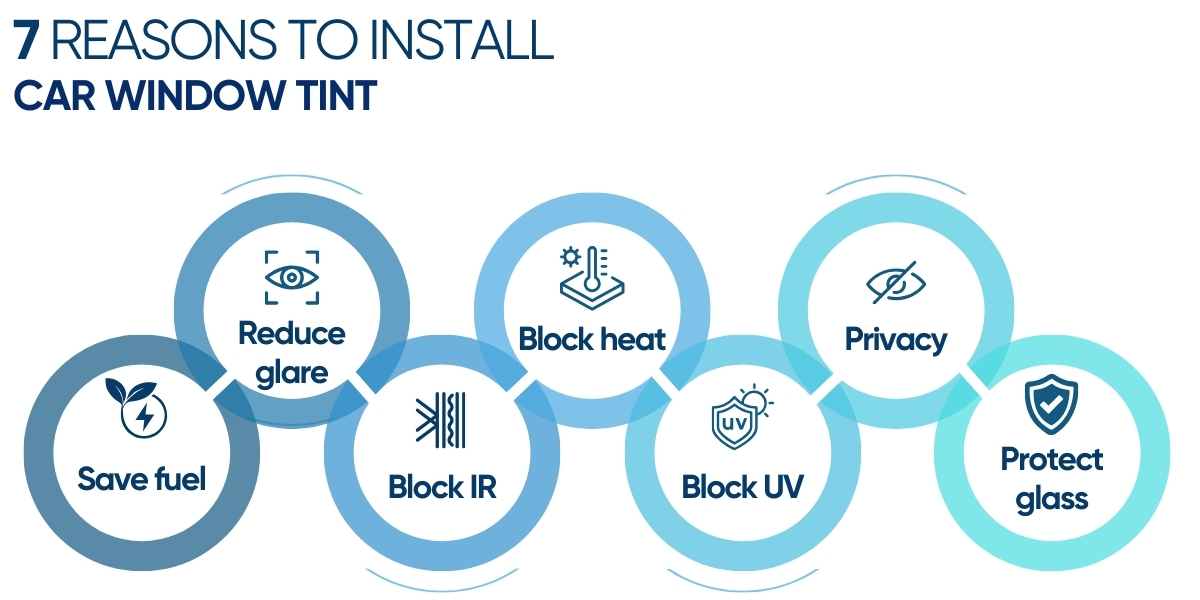

Is it necessary to apply car window tinting film?

Nowadays, applying heat-insulating film to cars is considered a ‘must-have’ accessory, especially in tropical climates with intense heat like Vietnam. However, many people are still concerned and question whether car window tinting film is really effective.

Car window tinting film has been researched, developed, and manufactured using advanced technologies. The film can significantly reduce the amount of heat transmitted through the glass. This is clearly demonstrated through technical specifications and can be verified using specialized tools as well as real-world experience. In addition to preventing heat and sunlight, applying heat-insulating film also enhances comfort with many other practical benefits.

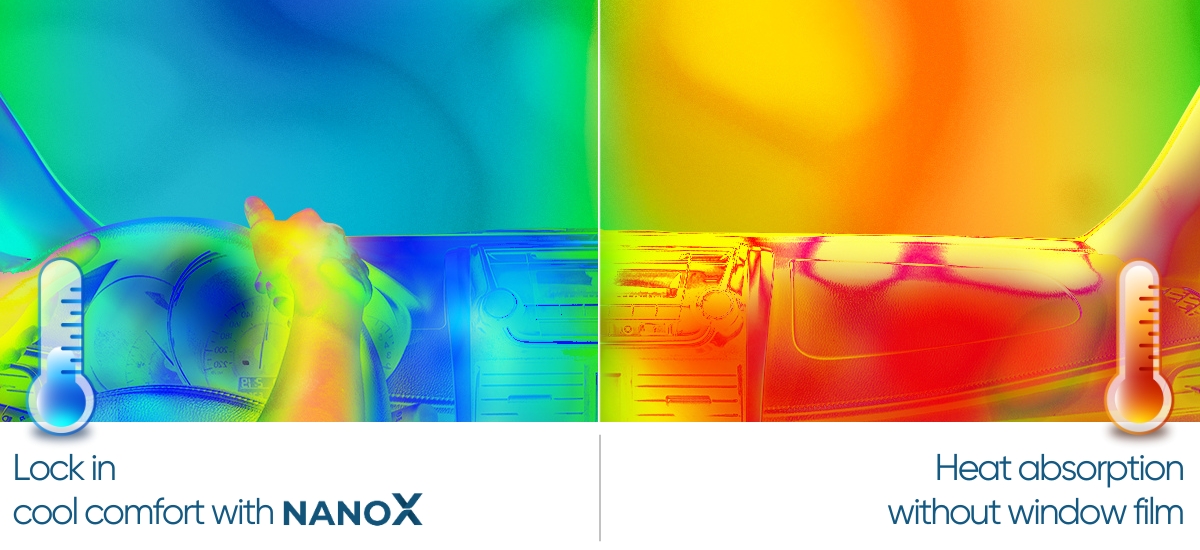

Heat insulation and sun protection: Car window tinting film helps block heat from being transmitted inside the vehicle. The cabin temperature is kept stable, significantly reducing the discomfort of sitting near the glass under the sun.

Infrared (IR) radiation rejection: High-quality car window tinting films have the ability to block infrared rays, thereby raising the overall heat rejection index to the most ideal level.

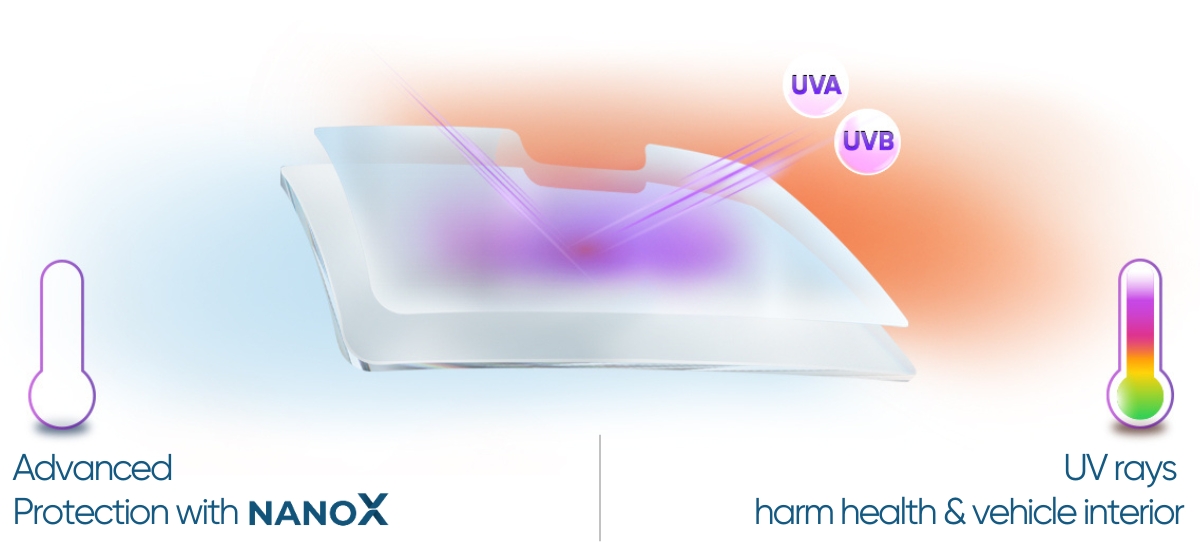

Ultraviolet (UV) radiation rejection: Most car window tinting films block 99% or more of UV rays, helping protect the skin and vehicle interior from UV damage.

Glare reduction: Car window tinting films have intelligent light filtering capabilities, helping reduce strong sunlight or headlight glare from oncoming vehicles.

Fuel saving: Applying car window tinting film not only prevents sunlight and heat from entering the vehicle, but also limits the loss of cool air from inside. Both of these contribute significantly to reducing the load on the air conditioning system.

Privacy enhancement: Car window tinting films can help reduce prying eyes from the outside thanks to the light difference mechanism between the interior and exterior environments.

Glass safety enhancement: Car window tinting film also acts as a protective film, reducing risks in the event of shattered or broken glass.

Meaning of Car Window Tint Specifications

Technical specifications indicate the level of heat rejection as well as other extended features of automotive window film. These specifications can be used to compare, evaluate, and choose high-quality and suitable window tinting films for vehicles.

Total Solar Energy Rejected (TSER): Indicates the film’s ability to reject heat transmitted through the glass.

Infrared Rejection (IRR): Indicates the film’s ability to reject infrared rays passing through the glass.

Ultraviolet Rejected (UVR): Indicates the film’s ability to reject ultraviolet rays passing through the glass.

Visible Light Reflectance (VLR): Indicates the level of reflectivity or mirror effect of the film.

Visible Light Transmission (VLT): Indicates the brightness or darkness of the film.

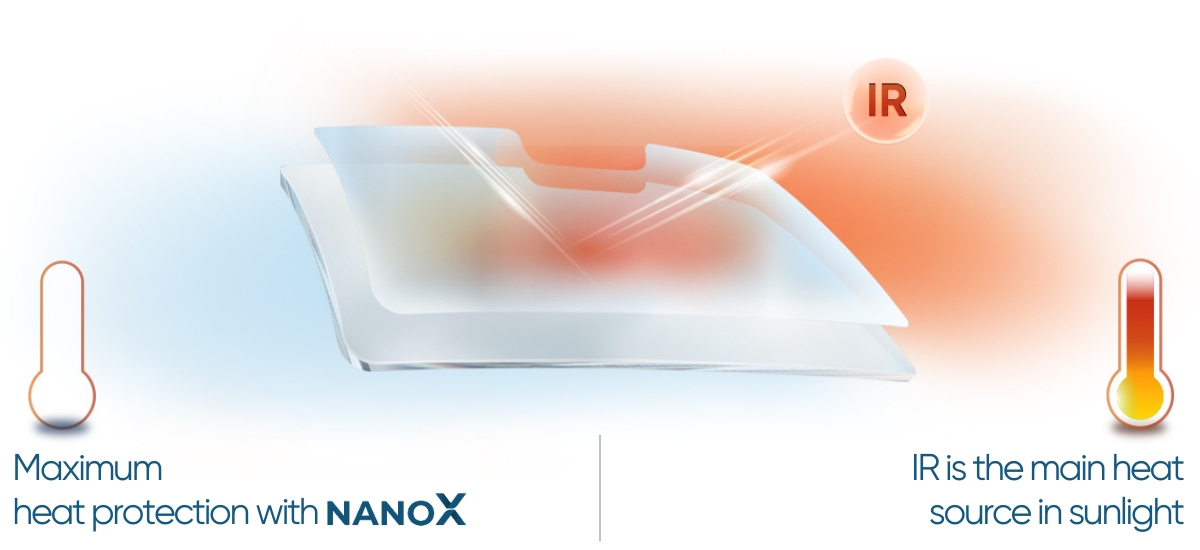

Among the above specifications, infrared rejection and visible light transmission directly affect the total solar energy rejection. This is because UV rays account for only about 3% of the sun’s heat. The highest portion comes from infrared rays, which account for approximately 53%. The remaining approximately 44% comes from visible light.

How to Choose Suitable Car Window Tint

When tinting car windows, the following guidelines should be considered to choose a high-quality heat insulation film that meets practical needs.

Choose Based on Manufacturing Technology

Car window tints are classified into 5 main groups based on manufacturing technology, including:

- Dyed Tint

- Metalized Tint

- Sputter Tint

- Nano Ceramic Tint

- Hybrid Tint

So, which type of window film should be used for cars? Nano Ceramic and Sputter Tint films are the most commonly used. However, Sputter Tint film is quite expensive due to high production costs. Meanwhile, Nano Ceramic film is more reasonably priced, effectively blocks heat, remains transparent, and is highly durable (as it uses non-metallic materials), making it more popular.

Choose Technical Specifications for Each Glass Position

Car windows are located in different positions with various functions. Therefore, it is advisable to choose compatible heat-insulating window film for each type of glass to maximize efficiency. The technical specifications of the film can indicate which type is suitable for which window position.

Front Windshield

The front windshield is the most important window and also the most affected by sunlight. This is the main cause of heat absorption in cars. Particularly, people sitting in the front seats often feel uncomfortable due to the heat radiating in.

Therefore, the window film for the front windshield should have the best heat and infrared rejection. The total solar energy rejection should be at least 50%, ideally 65% or more. To achieve this, infrared rejection must be at least 80%.

An important point when tinting the front windshield is visibility. The film’s visible light transmission must be at least 40–50% to ensure a clear view for the driver.

Front Side Windows

Front side windows are often exposed to sunlight from one side depending on the direction of the car. The driver or front passenger may feel heat due to proximity to the window.

When choosing window film for the front side windows, heat rejection is still a priority. However, unlike rear windows, they should not be too dark, as the driver needs to see the side mirrors. Thus, the film should balance between heat rejection and visible light transmission. In this case, a film with visible light transmission of 20–40% and total heat rejection over 70% is optimal.

Rear Side Windows, Quarter Glass, Rear Windshield

Unlike the front side windows, the rear side windows, quarter glass, and rear windshield do not have strict requirements for visible light transmission. Therefore, the transmission level can be selected based on personal preference. However, since visible light transmission directly affects heat rejection, films with low transmission (below 20%) can be chosen to achieve the highest total heat rejection for these positions.

Sunroof

The sunroof tends to get very hot due to direct vertical exposure to sunlight. If tinting this area, it’s best to choose a film with the highest total heat rejection.

Choose Based on Color

Automotive window films come in a variety of colors, including main color groups such as: ocean blue, light gray, dark gray, black, etc. You can choose the film color based on your preference, needs, or to match the car’s color scheme.

For example, if you prefer a cool and soothing view, a front windshield with an ocean blue tint is ideal. If you want color consistency and more privacy, you can choose a light gray film for the front windshield and darker shades like dark gray or black for the remaining windows.

How to Check for Genuine Automotive Window Tint Film

Nowadays, there are many tools and methods available to help check and distinguish between genuine, high-quality automotive window tint films and low-quality or counterfeit ones.

Check Technical Specifications: The technical specifications of automotive window tint film can be verified using specialized industry equipment.

Check Heat Rejection Capability: The actual heat rejection effectiveness of the film can be tested using an infrared lamp or verified with a thermometer.

Check for Clarity: To avoid affecting visibility—especially for the front windshield—automotive window tint must ensure high clarity. Avoid films that appear hazy, blurry, glaring, or foggy.

Check Brand Logo: Most genuine automotive window tint films are printed with a product code along with the brand’s logo.

Physical Inspection: It is important to inspect the physical condition of the film. Avoid films that show signs of scratches, peeling adhesive, uneven color, or waviness.

Check Warranty Policy: Most reputable automotive window tint film providers offer clear warranty policies to protect customer rights after purchase. Some even offer electronic warranty systems for convenience.

Check the Brand/Distributor’s Reputation: It is best to choose window tint films provided by reputable brands or authorized distributors that offer transparent information about their business and products.

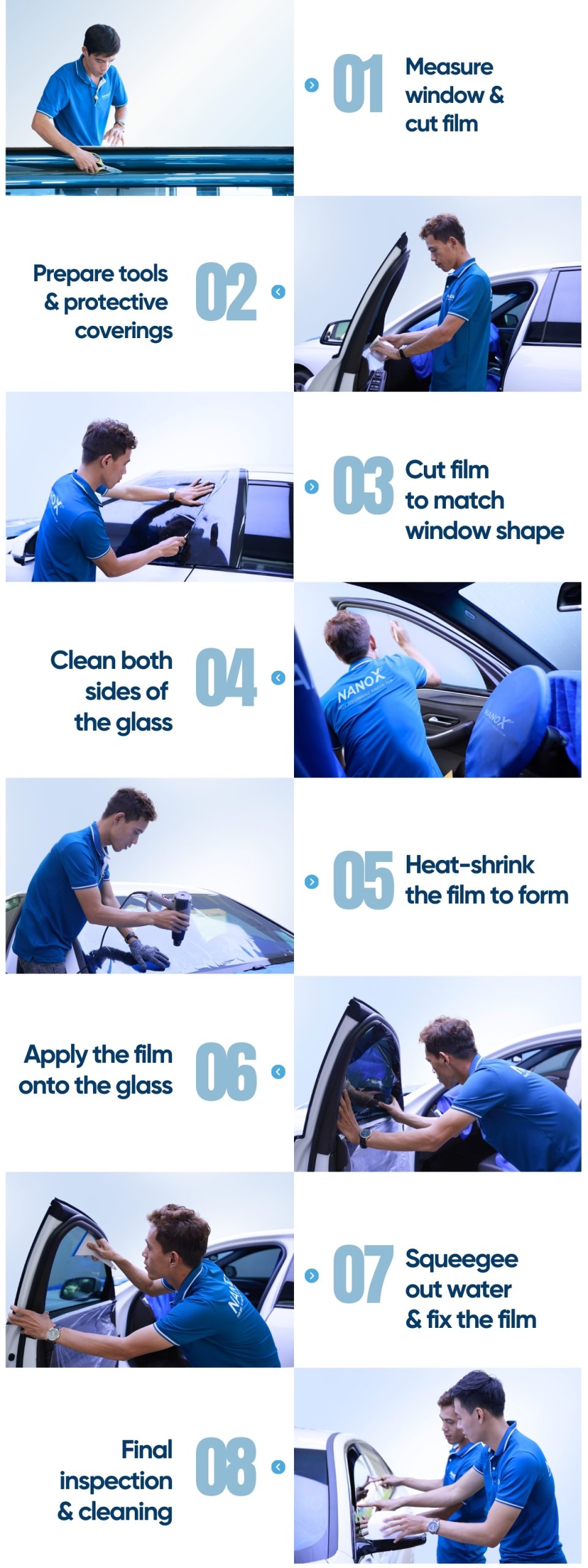

Steps to Apply Automotive Window Tint

Step 1: Measure the window & cut the film

Step 2: Prepare tools & cover interior for protection

Step 3: Clean the inside and outside surfaces of the glass

Step 4: Cut the film to match the window shape

Step 5: Heat-shrink the film to shape

Step 6: Apply the film onto the glass

Step 7: Squeegee out the water and secure the film

Step 8: Final check and cleaning

Post-Installation Notes for Automotive Window Tinting

After applying window tint to your car, it’s important to follow some key precautions to preserve the film’s durability and performance:

Within the First 24 Hours After Installation:

- Do not roll the windows up or down.

- Do not attach accessories to the windows (e.g., dash cams, sunshades, etc.).

- Avoid touching, pressing, or cleaning the inner surface of the glass.

These actions can cause the film to shift or peel off, as the adhesive has not fully cured during this period.

During Regular Use:

- Avoid using strong chemical cleaners on the inside of the glass. Use a soft cloth dampened with water to gently wipe the film surface.

- Do not scratch, rub with sharp objects, or expose the film to high heat sources (like lighters) near the glass.

- If you notice any issues with the film, do not attempt to fix it yourself. Instead, bring the vehicle back to the installer or brand representative for professional repair or warranty service.

Following these guidelines will help extend the lifespan of your automotive window tint and ensure optimal heat and UV protection.

NanoX – Brand and Address for High-Performance Automotive Window Film Installation

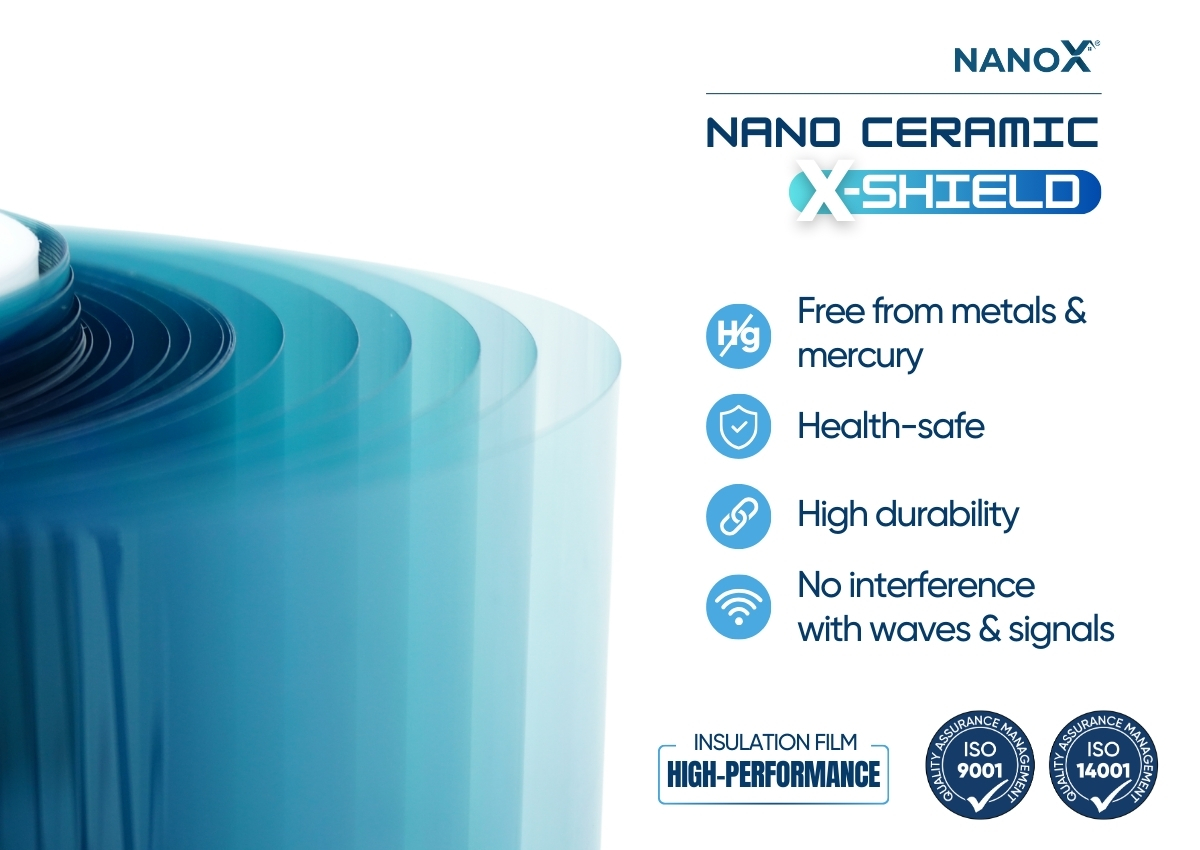

NanoX is a brand of residential and automotive window films developed in Vietnam by NanoFilm Trading and Service Co., Ltd. in collaboration with Korea. Possessing superior Nano Ceramic X-Shield technology, NanoX is proud of its powerful automotive heat rejection films that completely block harmful rays, offer ultra-clear visibility, and long-term durability. A special point is that this technology platform has been improved and optimized to deliver products to customers at the best possible price.

By choosing NanoX, customers will receive a heat insulation solution with unique value:

Effective: Genuine heat insulation product – genuine value.

Reliable: Ready to verify heat rejection performance & long-term warranty policy.

Good price: Good price thanks to innovation & optimization.

NanoX Products & Services

NanoX automotive window film products are specifically developed for all car window positions including: front windshield, front side windows, rear side windows, rear windshield, and sunroof.

NanoX provides automotive window tinting services at showrooms with specialized film installation rooms and at-home installation (free of charge).

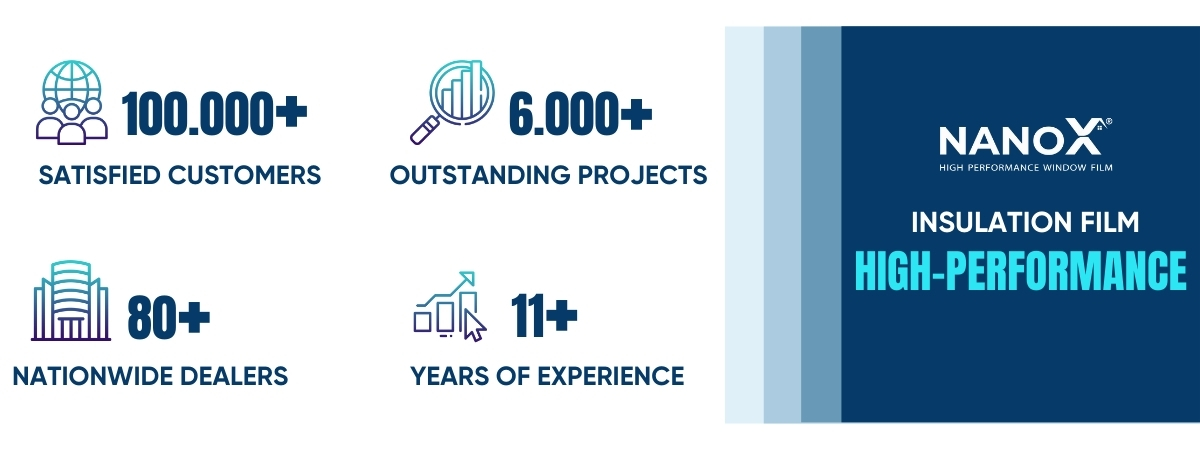

NanoX’s Achievements in Vietnam

With a solid foundation of over 12 years of industry experience, NanoX has quickly established itself as a leading brand in the window and automotive film market in Vietnam. Today, NanoX’s network of more than 80 dealers spans the entire country, delivering high-quality products and services to customers nationwide.

Features of NanoX Automotive Window Film

NanoX automotive window film offers seven outstanding features:

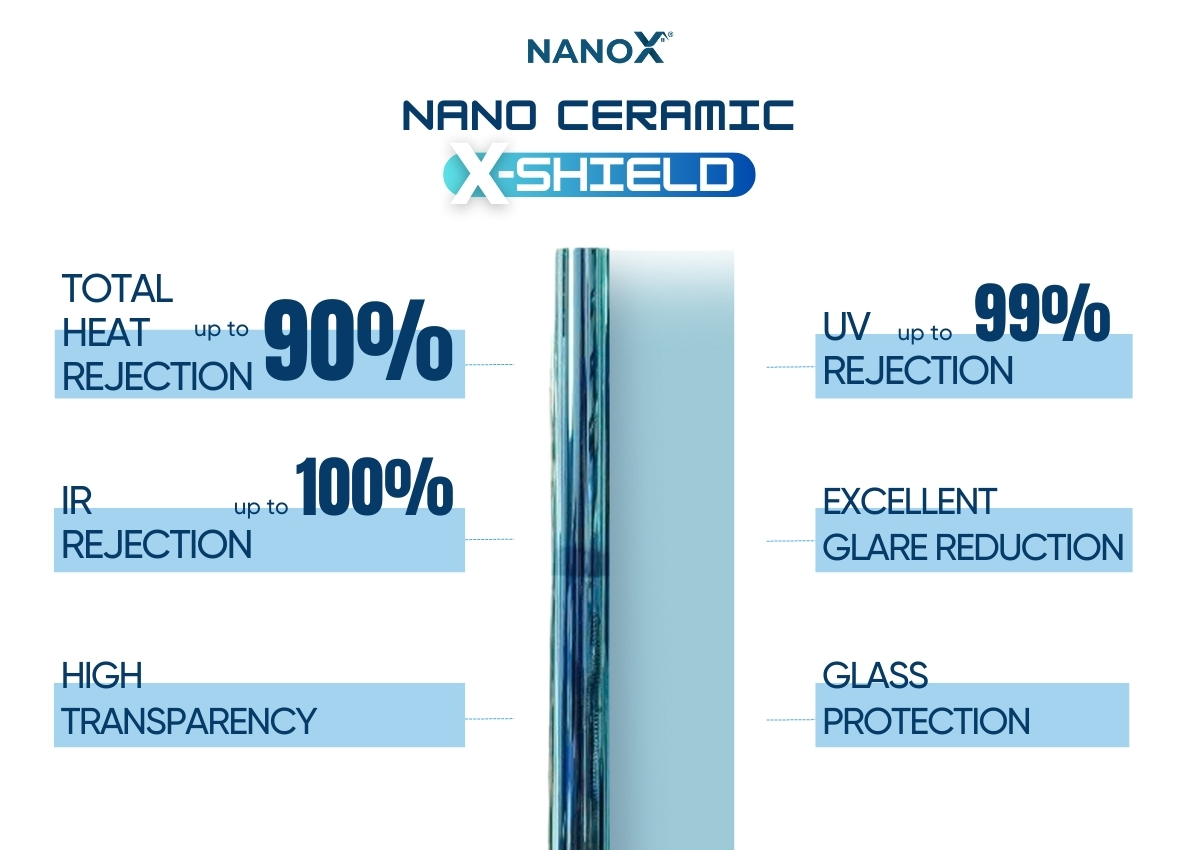

High Heat Rejection Efficiency – up to 90%

With a Total Solar Energy Rejected (TSER) rate of over 90%, NanoX window film acts as an effective barrier—regulating part of the visible light spectrum while nearly eliminating infrared rays.

The film absorbs solar energy and reflects it outward, preventing heat from entering the vehicle. This significantly reduces the discomfort caused by direct sunlight through windows, creating a cooler and more comfortable driving experience.

Blocks Up to 100% of Infrared Rays

NanoX automotive window film achieves up to 100% Infrared Rejection (IRR). Infrared rays are the primary source of heat in sunlight, and NanoX effectively eliminates this radiation entirely.

Unlike traditional films that reduce heat mainly by darkening visible light, NanoX uses advanced technology to filter out infrared rays without compromising brightness. As a result, NanoX offers light-colored films specifically for windshields—maintaining clear visibility while still delivering superior heat rejection.

Blocks Up to 99% of UV Rays

NanoX automotive window film offers up to 99% Ultraviolet Rejection (UVR). It is equipped with a UV filtering system that prevents harmful UV rays from passing through the glass.

This not only protects the health of passengers—reducing risks to the skin and eyes—but also preserves the vehicle’s interior. UV protection helps prevent damage and fading to materials like leather dashboards, seats, and steering wheels.

Exceptional Clarity

NanoX window film boasts a haze level of less than 1—a standout advantage, especially for windshield applications. While delivering maximum heat rejection, NanoX films maintain exceptional optical clarity.

Thanks to NanoX’s advanced Nano Ceramic X-Shield technology, light can pass through the film with minimal scattering. This ensures a crystal-clear view and an optimal visual experience for the driver.

Reduces Glare

NanoX automotive window film reduces glare by over 40% on windshields and more than 90% on other windows. It effectively softens intense light sources such as direct sunlight or oncoming headlights.

This not only enhances visibility for the driver but also reduces eye strain, providing a safer and more comfortable driving experience—especially during long trips or nighttime driving.

Privacy Protection

NanoX window film offers ultra-low Visible Light Transmittance (VLT), with options as low as 5% for side and rear windows. The lower the VLT, the better the film is at preventing unwanted outside visibility.

NanoX provides a wide range of film options with VLT levels ranging from 30% down to 5%, allowing users to choose the level of privacy they prefer. This enhances personal privacy while also improving security—especially when parking in public areas.

Enhanced Glass Safety

NanoX automotive window film features a thickness of up to 2.2 mil for windshields and 2 mil for other windows. This added thickness strengthens the glass, providing an extra layer of protection.

In the event of impact or breakage, the film helps hold shattered glass together—significantly reducing the risk of injury and enhancing overall safety for passengers.

NanoX Automotive Window Film Technology

NanoX’s heat-insulating automotive window films are manufactured using Nano Ceramic X-Shield technology. This cutting-edge innovation is built upon advanced material science and is specially optimized to suit the climate conditions of Vietnam.

By leveraging this proprietary technology, NanoX ensures superior heat rejection, UV and IR protection, and long-lasting durability tailored for tropical environments.

Nano Ceramic X-Shield – Advanced Inorganic Ceramic Technology

At the core of Nano Ceramic X-Shield is inorganic ceramic (technical ceramic glaze)—a highly advanced and heat-resistant material. This type of ceramic delivers outstanding thermal insulation, superior resistance to harsh environments, and is completely safe for users’ health. It also ensures zero interference with electronic signals.

NanoX uses ultra-fine ceramic particles, engineered through high-temperature processing to reach a nanometer scale as small as 28 nm—much smaller than the typical 50–100 nm range. These highly pure particles form exceptionally strong molecular bonds, which significantly increase the durability of the film while enhancing its ability to absorb and reflect solar radiation.

This results in a high-performance window film that not only lasts longer but also performs better in protecting your vehicle and passengers from heat and harmful rays.

Why Choose NanoX Automotive Window Film?

High-Performance Heat Rejection

NanoX is committed to delivering truly effective heat-insulating automotive films with genuine quality—at the best value.

Proven Performance

NanoX is ready to support you in testing the real-world heat rejection performance of our products before you decide to buy.

Professional, Technically Precise Installation

- Ensures flat, smooth film surface after application.

- Guarantees aesthetics: no peeling, cracking, or bubbling.

- All film edges are trimmed 1–2 mm inside the window frame.

- No film splicing during installation.

- Film is applied to the inner side of the glass panels.

Warranty in Accordance with Official Policy

- Warranty period ranges from 10 years to Lifetime, depending on the product line.

- During the warranty period, if any issue arises due to manufacturing defects or installation errors, NanoX will take full responsibility to repair or replace within 48 hours of receiving customer notice.

Customer-Centric Service

- Consultation tailored to your actual needs.

- Free on-site installation for full-package orders.

- Free removal of old film & glass cleaning.

- Dedicated 24/7 support.

NanoX Automotive Window Film Installation Process

NanoX follows a standardized process for automotive window film installation, based on the principles of professionalism, efficiency, and speed.

Step 1: Consultation Based on Customer Needs

Step 2: Select the Suitable Film Package

Step 3: Professional Film Installation

Step 4: Completion & Handover

In addition to in-store installations at official showrooms and authorized dealers nationwide, NanoX also offers free full-package at-home automotive window film installation services.

Frequently Asked Questions About Automotive Window Film

How much does it cost to apply NanoX automotive window film?

Answer: The full-package price for NanoX automotive window film ranges from 3,500,000 to 9,000,000 VND per vehicle.

Can people still see inside the car after applying the film?

Answer: NanoX window film significantly reduces outside visibility thanks to its light-filtering properties. It helps maintain privacy and gives you peace of mind when parking in public spaces.

How long does it take to install the film?

Answer: For 4- to 7-seater vehicles, installation typically takes 2 to 3 hours. If your vehicle already has old film applied, extra time will be needed to remove it and clean off any adhesive before the new film is installed.

Will applying window film affect vehicle inspection (registration)?

Answer: No, applying window film does not affect vehicle inspection. It is fully compliant with registration standards.

Can I be fined for using automotive window film?

Answer: No, there are currently no legal regulations prohibiting the use of automotive window films in Vietnam, so you won’t be fined.

What are the benefits of using automotive window film?

Answer: The main benefit is heat reduction. In addition, window film helps block UV rays, reduce glare, save fuel, and enhance glass safety, making driving more comfortable and secure.

NanoX Genuine Window Insulation Film from Vietnam

- Hotline: 0777.888.797

- Website: https://nanoX.vn/

- Email: contact@nanoX.vn

- Showroom: No. 2, Road 34, Van Phuc Urban Area, Hiep Binh Phuoc, Thu Duc, Ho Chi Minh City